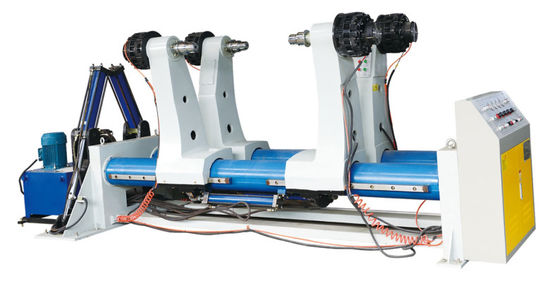

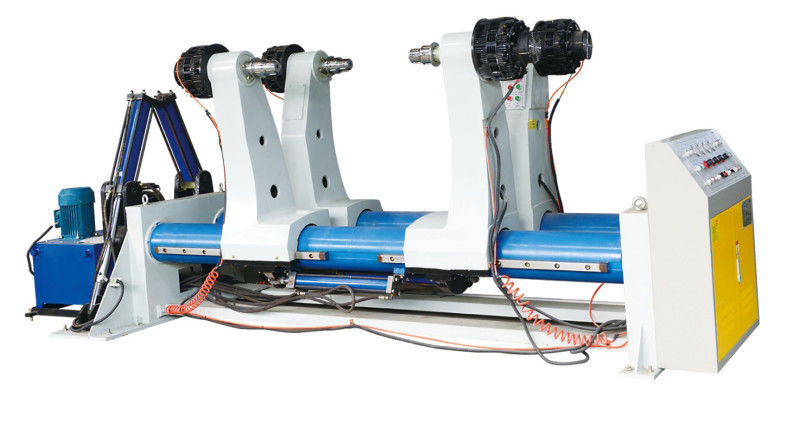

5.5kw Shaftless Mill Roll Stand For Automatic Carton Machine

Product Details:

| Place of Origin: | cangzhou,hebei,china |

| Brand Name: | Aomei |

| Certification: | ISO9001 |

| Model Number: | LUM-B |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | 50000-100000USD |

| Packaging Details: | as per need |

| Delivery Time: | 5-8 WORK DAYS |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 1SET/5 DAYS |

|

Detail Information |

|||

| Type: | Packing Line | Expiry Wideth: | 800-2200mm,clam Paper Diameter:max:1500mm,min:350mm |

|---|---|---|---|

| Single Arm Max Load Weight: | 3ton | Applicable Industries: | Manufacturing Plant, Food & Beverage Factory |

| Warranty: | 1Year | Place Of Origin: | Cangzhou,hebei.china |

| High Light: | 5.5kw Shaftless Mill Roll Stand,5.5kw Mill Roll Stand,Mill Roll Stand For Carton Machine |

||

Product Description

corrugated paperboard production line 3/5/7 ply hydraulic shaftless mill roll stand

LUM-B Hydraulic shaftless mill roll stand

Main technical parameters:

| No. | Name | Technical parameters |

| 1 | Effective working width | 800--2500mm |

| 2 | Mill roll stand action mode | Full hydraulic action |

| 3 | Paper diameter | Max:1500mm Min:350mm |

| 4 | Single side maximum load | Max :3000kg |

| 5 | Main roll diameter | Φ240mm |

| 6 | Hydraulic cylinder operating range (swing) | Φ100mm×460mm |

| 7 | Hydraulic cylinder diameter (clamping) | Φ63mm×720mm |

| 8 | Hydraulic station motor power | 5.5kw |

Structure features:

1. Symmetric structure can also install two original paper rolls, paper for non-stop for the job.

2. Hydraulic drive, to be completed by paper lift, clamp, loosen, move the pair.

3. Pneumatic tension adjustment paper tension. Jam head with automatic expansion.

4. Muti-point type tension control pneumatic brakes, but also with splicer line control.

Main outsourcing parts, raw materials and origin:

1.Bracket spindle: high quality thick-walled seamless steel Origin: Chengdu

2. Sides of the clamp arm panels and uses: HT200 cast Origin: Hebei

3. Main beam connecting channel: 280mm Origin: Angang

4. Bearing: selection Kazakhstan, tile, Los production

5. Appliances category: Zhejiang CHINT production

6. Pneumatic components categories: AirTAC, Zaozhuang Origin: Taiwan, Shandong

7. Hydraulic Class: North liquid Group (Ward) Location: Beijing, Shandong Zaozhuang

1)Ground rail and two paper carriages:

Technical parameters:

1 Applies to tile line width: 2500mm

2 Dimensions:. 6000mm×550mm×400mm (L × W × H)

Structure features:

1.Electric will base paper delivery in place, lightweight flexible.

2.Track overall buried, the main frame for 16 channel steel welded, strong and durable.

3.Cover plate installation after welding.

With two stage car from two side on paper paper.

Raw materials and related:

1.Rail and tractor materials: tang steel, jinan in profile

2.Bearing: HRB brand was produced by HAERBIN .LUOYANG CITY

2)Auto splicer

Technical Parameters:

1. Design speed: 150m/min

2. Diameter of max paper: 1500mm

3.When used with automatic tension control mill roll stand,it becomes high speed and high efficiency.

4.Without tail splicing,it will reduce paper consumption.

5.Splicing car out automatically when removed,and the vacuum absorption,easy paper loading,automatic tension control.

Detailed information:

When using automatic high-speed splicer,it’s more economical and practical.For example,production of eight hours per shift, shift splicing 40 times, each time output bin can save paper 300 meters long.If so,one year,in total, can save paper 100, 000 m long, a splicer paper can save 50 tons each year.

Using automatic high-speed splicer,it can increase production speed 1, 200 meters long per hour on average.Totally,a shift will produce paperboard more 9, 600 meters than before.

High-speed Automatic Paper Feeding Machine,it use double buffer roller power system and PLC control system. Meanwhile, the use of pneumatic proportional valve system, according to production orders, paper quality and other related parameters,it always keep paper tension constant.

High-speed tension control system is simple,rapid and flexible. Besides,it also can apply to domestic high, middle and low-grade production line.Therefore,it achieves high-speed receiving paper automatically fast and efficiently.

Technology Parameter:

| Max working width | 1400/1600/1800/2000mm |

| Min working width | 600mm |

| Max paper roll diameter | 1500mm |

| Single Side carriage | 2500kg |

| Air pressure | 0.6-0.9Mpa |

| Power | 4.5kw |

| Speed | 120-180m/min |

| Drive | Hydraulic |

Features:

l Symmetrical structure can install two rolls of paper at the same time and continually change paper roll;

l It adopts motorized control clamping, loosen, up-down, movement, contraposition, translation .

l Equipment was made of HT200-wide casting

l It adopts pneumatic braking.

l Electrical components are controlled centralized(domestic brand)

l Adopt hydraulic drive to complete the paper clamping, loosen, remove for the medium, translation left and right and others,the lifting of the paper adopts hydraulic drive.

l Brake adjustable adopts multi point braking system.