Automatic 380v Hydraulic Paper Mill Roll Stand Shaftless To Cardboard Production Line

Product Details:

| Place of Origin: | CN |

| Brand Name: | Aomei |

| Certification: | ISO9001 |

| Model Number: | LUM-2022 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | 10000 - 12500 USD |

| Packaging Details: | plastic film |

| Delivery Time: | 45 days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 25sets per mnoth |

|

Detail Information |

|||

| Driven Type: | Electric,Hydraulic | Weight: | 2500 - 3000 KG |

|---|---|---|---|

| Voltage: | 220V/380V,Customer's Demand,380/440V | Application: | Machinery & Hardware,Commodity,Food,Chemical,Apparel |

| Type: | Packaging Line,electric Mill Roll Stand/automatic Carton Making Machine,Mechanical Or Hydraulic | After-sales Service Provided: | Engineers Available To Service Machinery Overseas |

| Condition: | New | Packaging Material: | Corrugated Paperboard |

| Packaging Type: | Cartons,Film | Automatic Grade: | Automatic |

| Power: | 4KW | Warranty: | 2 Years |

| Name: | Paper Roller Hydraulic Mill Roll Stand,Carton Box Making Machine,Mill Roll Stand Machine | Usage: | Making Carton,Making Corrugated Cardboard,Hydraulic Mill Roll Stand Of Corrugated Cardboard Packing Machine |

| Function: | Electric Carton Packer,Holding Paper Roll For Machine | Machine Type: | Hydraulic Type,Corrugated Paperboard Making Machine,Hydraulic Drive |

| Keywords: | Mill Roll Stand,Roll Stand For Corrugated Paper,Production Machine | Color: | As Customer Required |

| Highlight: | automatic hydraulic paper mill roll stand,380v hydraulic paper mill roll stand,shaftless automatic hydraulic mill roll stand |

||

Product Description

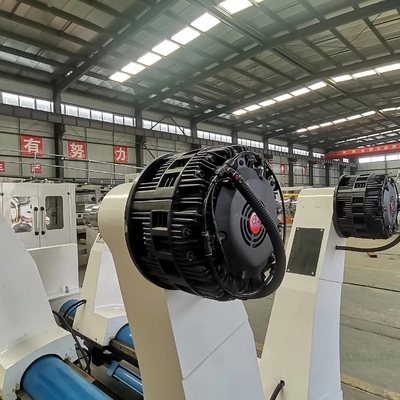

Automatic 380V Hydraulic Shaftless Mill Roll Stand Of Cardboard Production Line

Automatic 380V Hydraulic Shaftless Mill Roll Stand Of Cardboard Production Line

The original paper frame is used to load the rolled paper, so that the rolled paper can be easily and smoothly bonded with the face paper to form corrugated board through the corrugated roller under the action of tension. The structure of the original paper frame is relatively simple, mainly including the frame, the lifting device, the tension control device, the deviation correction of the paper web and the loading and unloading of the paper roll. Usually, each single-sided machine is equipped with two base paper racks, which are located at the front and rear of the single-sided machine respectively: one supplies corrugated base paper, and the other holds face paper or lining paper.

According to the different structural forms, the base paper frame can be divided into two types: shaft and shaftless. Axle support means that the paper roll rests on its core.

Shaft support, the equipment structure is simple, the price is economical, and the bracket is provided with a manual deviation correction device and a tension control system. Axle-less bracket mainly uses clamping cone head to support paper roll from two ends inserted into the paper roll core. When the machine is running, under the action of tension, the paper roll can rotate freely and stably along the cone head. When the clamping cone head works, it rotates with the paper roll, and a brake is installed on the clamping cone head rod to control and adjust the tension of the paper web.

At present, the rotary shaftless paper support is commonly used in the domestic corrugated board production line (Figure 2-4). It can be seen from the structural diagram of the bracket that two raw paper reels can be loaded on the bracket at the same time: one reel is for use and the other reel is for standby. This kind of structure can realize continuous production without stopping the machine when changing the paper roll. At present, most of the high-speed corrugated cardboard production lines use the internal expansion chuck instead of the original hexagonal cone head. The internal expansion chuck has a simple structure and does not need power assistance. The convex strip of the chuck can contract or relax along with the traverse of the base paper frame, and automatically expand and expand in the paper tube to fix the base paper, which solves the problem that the hexagonal cone head is easy to break the tail paper and improves the utilization rate of the tail paper.

Automatic 380V Hydraulic Shaftless Mill Roll Stand Of Cardboard Production Line

| Driven type | Electric, Hydraulic |

| Weight | 2500 - 3000 KG |

| Voltage | Customer's Demand |

| Condition | New |

| Name | Paper Roller Hydraulic Mill Roll Stand,Carton Box Making Machine,Mill roll stand machine |

| Keywords | Mill roll stand,Roll Stand for Corrugated Paper,Production Machine |

![]()