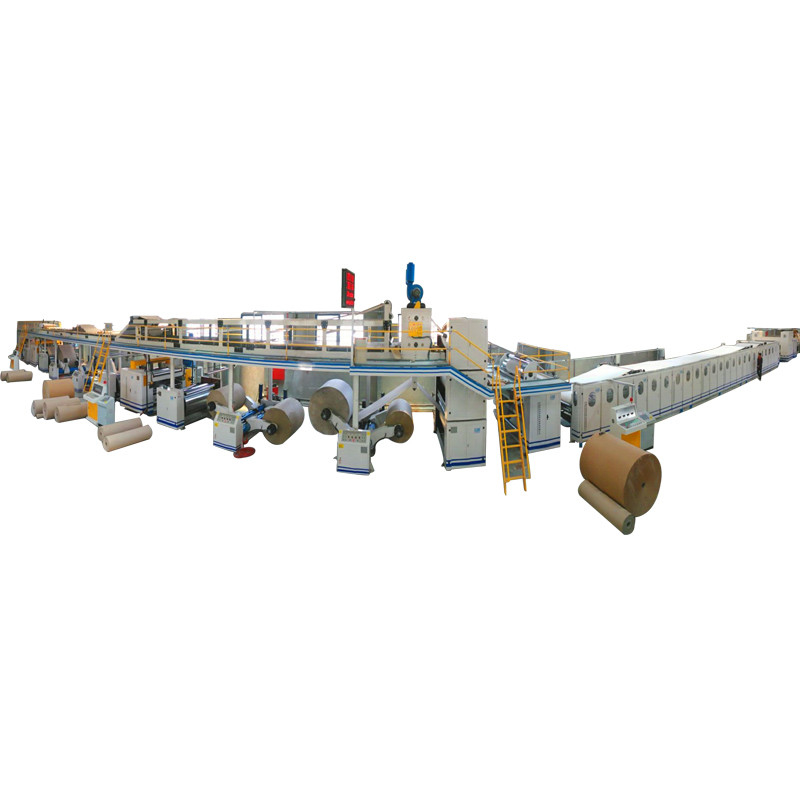

3 Layer Pizza Box Corrugated Cardboard Making Machine 380v Three Phases

Product Details:

| Place of Origin: | Dongguang,hebei,china |

| Brand Name: | Aomei |

| Certification: | ISO9001 |

| Model Number: | LUM |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | 150000-300000usd |

| Packaging Details: | as per need |

| Delivery Time: | 5-8work days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 1set/5days |

|

Detail Information |

|||

| Type: | Packaging Line | Application: | Food, MEDICAL, Machinery & Hardware |

|---|---|---|---|

| Packaging Type: | Cartons | Driven Type: | Electric |

| Place Of Origin: | Hebei, China | Name: | 3 5 7 Ply Automatic Paperboard Making Machine |

| Color: | Any Color | Voltage: | 380V, 220V/380V, 3Phases, 380V/50HZ, 220V/380V/440V |

| Highlight: | corrugated cardboard making machine 380v,three phases corrugated cardboard making machine,3 layer corrugated box automatic machine |

||

Product Description

Fully automatic 3 5 7 layer Corrugated Paperboard Making Machine production plant

1. Symmetric structure can also install two original paper rolls, paper for non-stop for the job.

2. Hydraulic drive, to be completed by paper lift, clamp, loosen, move the pair.

3. Pneumatic tension adjustment paper tension. Jam head with automatic expansion.

4. Muti-point type tension control pneumatic brakes, but also with splicer line control.

1.Hydraulic shaftless mill roll stand

![]()

Ground rail and two paper carriages:

1.Electric will base paper delivery in place, lightweight flexible.

2.Track overall buried, the main frame for 10 channel steel welded, strong and durable.

3.Cover plate installation after welding,with two stage car from two side on paper paper.

2.Fingerless type single facer machine

![]()

1. Apply vacuum adsorption for paper feeding, equipped with high-pressure powerful fan. Equipped with air conditioning machine air suction device;

2. Gimble transmission, the body structure independent driver box. Enclosed gear transmission oil lubrication, can prolong the service life of gear.

3. Glue-coating roller and fixed rubber roller design for group guide sliding, disassembling conveniently.

4. Base and wallboard cast iron structure, wallboard thickness for 180mm.

5. Corrugated roller adopts 48CrMo high quality alloy steel, via piece.modified, quenching, surface polishing, corrugated roller diameter Ø 320mm, surface hardness for HRC60 degrees, Corrugated roller adopt cylinder controlled fluctuation displacement

6. Pressure roller diameter(Ø320mm),surface treatment processing and chromium plating,Cylinder controlled fluctuation,material for medium-carbon steel displacement 45, modulation handle.

7. Corrugated roller and pressure roller bearings use high-temperature grease lubricated bearing.

8. Pneumatic control glue feeding, glue roller diameter (Ø240mm), surface polishing and engraved net with then hard chromium plating, glue adjusting roller hard chromium plating and grinding.

9. Adopt electric glue separating device, easy operation and well performance,PLC touch screen available.

10. Corrugated roller unilateral high 0.10 mm, pressure roller unilateral 0.075 mm high. Plus limit device, pressure cylinder for Ø 1.6 mm cylinder.

11.Electronic components and accessories: Schneider brand,TECO motor from Taiwan.

3.Over Transport Bridge

![]()

1.This part of the main beam is mainly connected by channel, beam, angle, column, etc connected together.

2.Both sides of the security fence, high strength and save people the word pedals, ensure operator safety and ease of operation.

3.Ascension pull paper axis, the tension axis, feeding off of the shaft, such as surface grinding hard chrome plating process.

4. Adopt adsorption tensioner tension adjusting device, the air volume is adjustable.

5.Correction device for the electric, easy to operate. Correction side fence with double guide column positioning screw driver, fast and accurate positioning, walking steadily.

6.All roller surface by grinding off the hard chrome plating process.

7.Feeding conveyor transfer using green plain.

4,5.Single layer and three layer pre-heater

1.Preheat cylinder pressure vessel meets a national standard, together with the pressure vessel certificate and inspection certificate.

2.Preheat cylinder electric wrap angle worm drive shaft, corners integrally connected with the cylinder axis of the structure.

3.Preheat the cylinder after each roll-off grinding and precision grinding hard chrome plating, improved finish reduces friction, durable.

4.With electric adjustment corners, corners can be adjusted within the range of 60-270 °, can effectively adjust the paper heated area.

5.Preheat the cylinder head using the butterfly design can improve the performance of the pressure cylinder; using steam heating to ensure uniform heating paper.

6.Corners motor with planetary cycloid pin wheel motors, and a good self-locking performance.

7.Electrical components centralized control, its components: use Shinaide brand,West Germany

8.Bearings are made of: Harbin Bearing

9.Pneumatic components, rotary joints, metal hose: AirTAC selection, Tengzhou Jin Xuan genuine products.

6.Secondary gluing machine

![]()

1.Paste glue roller and fixed roller with 45 steel, quenched the surface, the hole machining; do homeostasis surface grinding roller body engraved with pit-style textured, gluing evenly and consume more less.

2.Squeegee roller surface grinding and hard chrome plated.

3.Other roller of the paper guide roller and shaft is hard chrome plated.

4.Press paper roller up and down adopt pneumatic control, easy to operate.

5.The glue gap between the roller and roller squeegee using manual control or electric inverter control,PLC touch screen for option.

6.Automatic cycle for glue, glue to prevent sedimentation;

7.Preheat cylinder use Q235B container board, produced by professional manufacturers of pressure vessels, the preheating device, can accelerate the glue paste.

8.Bearings: Harbin Bearing.

9.Electronic components, accessories: adopt Schneider, Delix brand electrics.

10.Pneumatic component,rotary joints,metal hose: AirTAC selection, Tengzhou Jin Xuan genuine products.

7.LUM-B Double facer machine

![]()

- Whole rack adopt high-strength 40 # channel steel,tough structure and work steadily,glue rollerΦ270mm; cardboard thickness:130mm.Surface is grinded and plated chrome.

2.Hot plate 600x15 pieces,heating plate with high strength container board production, accords with national safety standards for pressure vessels. 600mm wide steel hot plate , inside S -shaped guide airflow structure , improve the utilization of steam. Many remain hot plate welded stiffeners never deformed . Pressure vessel with a certificate and inspection certificate .

3.Heating zone structure using intensive pressure roller or hot plate structure,cardboard stereotypes firm adhesion formation .

4.Steam pipe inlet,exhaust port by the S -shaped arrangement , hot plate temperature equilibrium and even.

5.Hot plate temperature control separately, height adjustment to adapt to the speed .

6. Heating section with electric or hydraulic roller weight overall increase , smooth movements , safe and reliable.

7. Choose a large hydraulic lifting belts, hydraulic station is 4.0kw.

8.Upper conveyor belt with automatic,manual correction device each 1set,tension pneumatic, manual adjustment each 1set;Lower conveyor belt with tension and corrective device adjustment.

9.Large diameter drive unit with a textured high- abrasion rubber,lower conveyor belt slippage and to prevent belt deviation;Improve the stability of operation of the device to ensure that the output level of cardboard .

10.Separate gear box drive,low noise,using oil immersion sealed gear;Optional electromagnetic speed motor or inverter motor drive .

8.LUM-B Thin Blade Slitter Scorer

![]()

1.The machine adopts the structure of convenient electric lift.

2.High quality tungsten alloy thin knife, sharpening device is equipped with both automatic and manual structure and convenient operation.

3.Wheel wire wheel pressure line using French technology lines and beautiful cardboard Martin should not be broken. According to user requirements with a four-or five-blade knife six-eight lines. 4.The machine speed can be synchronized with the host running the operation to reduce the staff alone. Lower production costs.

5.Can be tracked according to the operating position slitting cardboard. Reduced waste paperboard.

9.LUM-B NC Cut-off machine

![]()

Roller diameter parameter:

1.On the 1 cutting knife shaft diameter: Φ200mm handling of dynamic balancing

2 after the transfer roller diameter: Φ130mm handling of dynamic balancing

3 before and after the roller diameter: 70 mm

Note: The surface of all the roller are hard chromium plating after grinding. (Except for the upper and lower cutter shaft)

Power motor and electrical parameters:

1.Main drive motor power: 18.5kw; AC servo motor

2.Before and after transmission of paper motor power: 3.0kw; frequency adjustable speed motor

3.Oil pump motor power: 0.37kw

Main purchased parts, raw materials and production place:

1.Blade material: W18crv5Co5 (high speed tool steel)

2.Gear materials: 40Cr (finishing quenching and tempering treatment)

3.Bearing types: Hawaltto produced, Bearing seat: Shandong produced

4.Electrical appliance

10. LUM-B Automatic stacker machine

![]()

1.Automatically stack and collect the paperboard.

2.Pneumatic control the transversely output of paperboard, electrical ouput.

3.Vertical paperboard collecting use width belt for transportation.

4.When the paperboard stack to required height, the paperboard is output by switch controlled.

11.Gluing making system

![]()

1. To provide single-sided machine, secondary adhesive and other adhesive equipment to provide starch adhesive.

2. Horizontal system of plastic machine can be the main body of the preparation of plastic and plastic carrier, and mixing, the amount of plastic system.

3. Large round tank storage barrels of glue are pumped to the various plastic equipment used to store the storage barrels, for the equipment to provide glue.

4. The system of plastic storage bucket and storage bucket, for the plastic bucket own mixing device, to avoid glue precipitation caking.

5. The glue making device comprises a carrier tank, a main body tank, a storage tank and a feeding rubber pump and a back glue pump respectively.

6. The glue making system adopts the circulation glue, the glue flows to the bucket back to the plastic bucket, the liquid level float automatic control, the back glue side bucket's glue is hit with the rubber equipment storage bucket, carries on the circulation for Glue, save glue, to prevent glue gelatinization and agglomeration precipitation.

7. After the completion of the work, with more than plastic equipment, plastic was removed, the total pipeline pump back to the plastic storage bucket, for the next use.

12.13 Electric panel & Pneumatic system

14.Steam heating systems

1. For the whole production line with the transmission of heating equipment, heat energy, to maintain the stability of the working temperature.

2. Each unit is designed as an independent small unit for the steam system, sub-temperature control, energy conservation, easy to adjust.

3. By regulating the steam pressure on the implementation of the working temperature control, and a pressure monitoring dial.

4. Each set of hydrophobic units are equipped with emptying by-pass, cooling equipment quickly when shutdown.

5. Float trap, 1/2 metal hose and ball valve connected bypass, plug the plug valve.

6. The flexible connection between the piping system and the rotating heating element is achieved by a metal hose to extend the service life of the rotary joint.

7. All steam pipes are made of seamless steel pipe, to ensure the normal use of pressure under the security.