CE ISO Carton Used Corrugated Box Making Machine Fullyautomatic

Product Details:

| Place of Origin: | CN |

| Brand Name: | Aomei |

| Certification: | ISO9001 |

| Model Number: | 123-59 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | 1-50000 usd |

| Packaging Details: | woods |

| Delivery Time: | 45 days |

| Payment Terms: | L/C, Western Union |

| Supply Ability: | 30 sets per year |

|

Detail Information |

|||

| Voltage: | 220V/380V | Type: | Packaging Line |

|---|---|---|---|

| After-sales Service Provided: | Online Support | Condition: | New |

| Certification: | CE,ISO | Warranty: | 1-2 Years Warranty |

| Automatic Grade: | Automatic | Driven Type: | Electric |

| Highlight: | Used Corrugated Box Making Machine ISO,Used Carton Box Making Machine Fullyautomatic,used corrugated box making machine fullyautomatic |

||

Product Description

How Is The Corrugated Carton Made ?

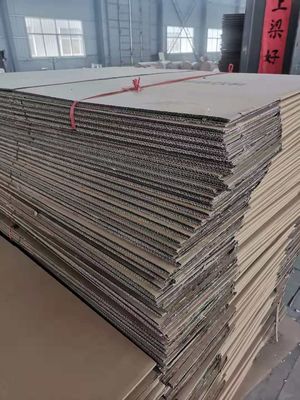

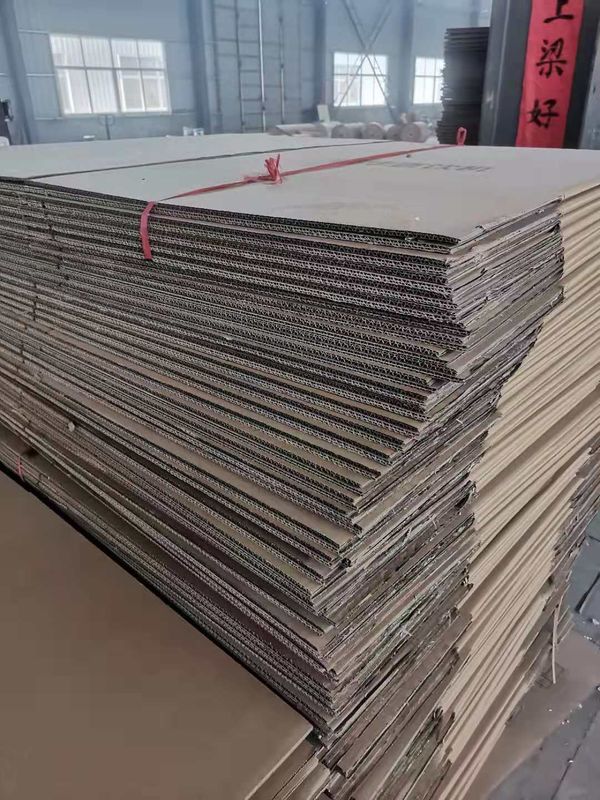

Corrugated paper board is made of face paper, inner paper, core paper and corrugated paper processed into corrugated corrugated corrugated paper by bonding. According to the demand of commodity packaging, corrugated board can be processed into single-sided corrugated board, three-layer corrugated board, five-layer, seven-layer and eleven-layer corrugated board.

Corrugated boards with different corrugated shapes have different functions. Even if the face paper and the inner paper of the same quality are used, the performance of corrugated board is different due to the difference of corrugated shape. There are four types of corrugated ridges commonly used in the world, which are A-type ridges, C-type ridges, B-type ridges and E-type ridges. See table 1 for their technical indicators and requirements. Corrugated board made of A-type corrugated board has better cushioning and elasticity, while C-type corrugated board is better than A-type Leng Ci. But stiffness and impact resistance are better than A-type stare blankly. B-type corrugated board has high density, and the surface of corrugated board is flat and high bearing pressure, which is suitable for printing; E-shaped stare blankly is thin and dense, which shows its rigidity and strength.

The difference between container and non-container mainly lies in the outer diameter, which is closely related to the corrugated type. The following table will detail the relationship among carton inner diameter specification, manufacturing specification and outer diameter specification:

Measuring method for manufacturing dimensions of corrugated boxes

The manufacturing size of carton is the blanking size when making carton. The manufacturing dimension is based on the pressing line on the unfolded box blank. The indentation roller on the slitting machine presses a groove at the line pressing position, and the line pressing is the center line of the groove. The distance between two pressing lines is the manufacturing dimension. Conversion of manufacturing dimensions into inner and outer diameter dimensions can be achieved quickly by Table 2, but they also have their own measurement methods.

Corrugated boxes can be divided into single and double spelling in the manufacturing process.

Single spelling is a one-page forming box, which is generally used for cartons with small circumference; Double-box is also called two-page box. Some cartons are too big in circumference, so they have to be pieced together with two blanks. However, sometimes, in order to make use of the surplus materials cut in the production process, carton factories will also use two pieces to piece together a carton which is not too big in size, and sometimes even use four pieces. Compared with the one-page box, the two-page box has one more joint, so there are some slight differences in the area calculation between them.

Joints and loops

The manufacturing dimensions of carton joints are determined according to corrugated layers and production process level, which are 35~40mm for single corrugated board, 45~50mm for double corrugated board and 50mm for triple corrugated board.

When calculating the unfolded area of carton, the loss of loop must be considered in the manufacturing process, and the size of loop is determined according to the number of layers of paperboard, which is generally 20 ~ 40 mm.

In order to facilitate the calculation in practical work, the rule of adding "8" and "4" is uniformly adopted, that is, the sum of joints and loops in the transverse direction is set to 8cm, and the total sum of loops in the longitudinal direction is set to 4cm.

1. Calculation formula of flat box area

Through the above introduction, the area calculation of the flat box can be expressed by the following two formulas:

The area of single carton is s = [(length+width) × 2+8] × (width+height +4)

The area of double carton is s = [(length+width+8) × 2] × (width+height +4)

[Note: The units of length, width, height, 8 and 4 are all in cm. 】

Expanded area of carton with upper full cover and lower socket.

Cartons with top full cover and bottom socket are generally small in size, some of which are made of corrugated cardboard, and some of which are produced only with single-layer coated white cardboard, such as small outer packaging of medicines, foods and cosmetics.

Cut length and tile height

In the manufacturing process of corrugated boxes, it is particularly important to distinguish the concepts of cut length and tile height. If you make a mistake, the strength of cartons will be thousands of miles away, which will lead to the scrapping of all produced cartons, resulting in huge losses.

Cut length refers to the length perpendicular to the corrugated direction; Tile height refers to the length along the corrugated direction.

Joints and loops

Here, the joint size is determined according to the number of carton layers. The joint of three-layer box is generally 3cm, and that of five-layer box is generally 4cm. The size of the loop is calculated by 2cm.

2. Calculation formula for the area of carton with top cover and bottom socket.

Cut length: L= (length+width) ×2+ joint+loop.

Height of tile: H=1/2 width+socket+height+width+wire return.

Area: s = l× h.

Note: Generally, the area of cartons is calculated with reference to physical objects. After the cartons are unfolded, the specific dimensions are analyzed according to the specific shapes of different cartons. The length, width and height are all fixed by accurate measurement, and the dimensions of joints and loops are flexible according to different situations.

Want to Know more details about this product