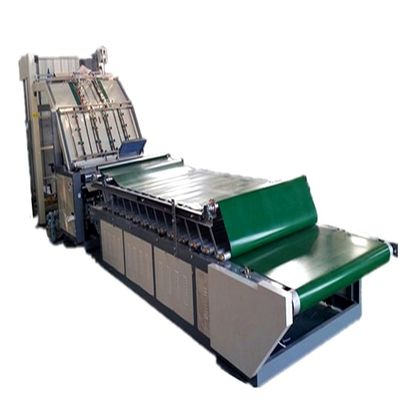

Intelligent 7.2T Automatic Flute Laminating Machine For Corrugated Carton

Product Details:

| Place of Origin: | China |

| Brand Name: | Aomei |

| Certification: | ISO CE ISO9001 |

| Model Number: | AD- Automatic flute Laminating Machine |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | 1220 |

| Packaging Details: | as per need |

| Delivery Time: | 35 days |

| Payment Terms: | D/A, T/T, Western Union |

| Supply Ability: | 1000sets |

|

Detail Information |

|||

| Automatic Grade: | Automatic Flute Laminating Machine | Weight: | 5T, About 3T, 450Kg, 3 Ton, 230kg |

|---|---|---|---|

| Driven Type: | Electric, Pneumatic, Hydraulic, Mechanical | After-sales Service Provided: | Engineers Available To Service Machinery Overseas, Online Support, Video Technical Support, Field Installation, Commissioning And Training |

| Type: | Laminating Machine, High Speed Semi-automatic Flute Laminating Machine, Laminating Machine And Flip Flop Machine | Application: | Machinery & Hardware, Food, Commodity, Medical, Beverage |

| Voltage: | 380V, 380V/50HZ, 220/380V, 380V/220V, 220v | Condition: | New |

| Dimension(l*w*h): | 7100*1850*1250, 30*3.5*3m, 12000*2550*2655mm, 11.5x2x2.4M, 6000mm*1800mm*2000mm | Packaging Material: | Wood, Paper, Plastic, Metal, Glass |

| Highlight: | 7.2T Automatic Flute Laminating Machine,Intelligent Automatic Flute Laminating Machine,7.2T Carton Laminating Machine |

||

Product Description

Fully Automatic Intelligent High Speed Flute Laminating Machine

Fully Automatic Intelligent High Speed Flute Laminating Machine |

|

| Max size | 1450*1300mm |

| Min size | 350mm*350mm |

| Speed | 0-100m/min |

| Total power | 12kw |

| Overall size | 12.0m*2.40m*2.655m |

| Weight | 7.2T |

|

Paper request |

Bottom paper : 350-800 800g/m2 Max thickness: 10mm |

![]()

![]()

![]()

1,Adopt unique press spring type FRONT LAY design which low rate of break down And with intelligent control can laminate paper in right position.

2,Adopt frequency convertor for speed regulation , PLC control , run and control rightly .

3,Double servo control are used to make bottom paper send to front lay timely and accurately . to promise machine working accuracy when machine run.

4,Glue roller and doctor roller work together to improve homogeneity of glue . will low cost glue for customer.

5,Steel roller through balanced processing and testing, with tight assembly process effectively improve the mechanical stability, combined with the main transmission . adopts the timing belt drive, bottom paper suction feeder directly, effectively improve the precision and speed of mechanical operation.

6,Glue level control system , automatic glue recycle , reduce worker labor.

7,Material are used for this machine according to ISO 90001 . good quality material , key part like bearing is imported. Electric part used all world famous brand and China well-known brand.

8,Self-develop high strength feeder compliant with high configuration electric system.

9,Suit 150-450 gsm face paper with A,B,C,D,,E,F flute 3 ply, 5ply cardboard (thickness less than 8mm )

Suzy yu (Sales Dept.)

Cangzhou AoMei Light Industry Machinery EQUIPMENT Co.,Ltd

Cangzhou City, Hebei Province China

Mob:+86-15903176289

E-mail:suzy@AoMeipack.com

QQ:174996398

Wechat:15903176289