Hydraulic Corrugated Cardboard Making Machine For Carton

Product Details:

| Place of Origin: | Dongguang,hebei,china |

| Brand Name: | Aomei |

| Certification: | ISO9001 |

| Model Number: | LUM |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1set |

|---|---|

| Price: | 150000-300000usd |

| Packaging Details: | as per need |

| Delivery Time: | 5-8work days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 1set/5days |

|

Detail Information |

|||

| Type: | Packaging Line | Application: | Food, MEDICAL, Machinery & Hardware |

|---|---|---|---|

| Packaging Type: | Cartons | Driven Type: | Electric |

| Place Of Origin: | Hebei, China | Name: | 3 5 7 Ply Automatic Paperboard Making Machine |

| Color: | Any Color | Voltage: | 380V, 220V/380V, 3Phases, 380V/50HZ, 220V/380V/440V |

| Certification: | CE ISO9001 | Warranty: | 2 Year |

| Highlight: | Hydraulic Corrugated Cardboard Making Machine,Corrugated Cardboard Making Machine For Carton |

||

Product Description

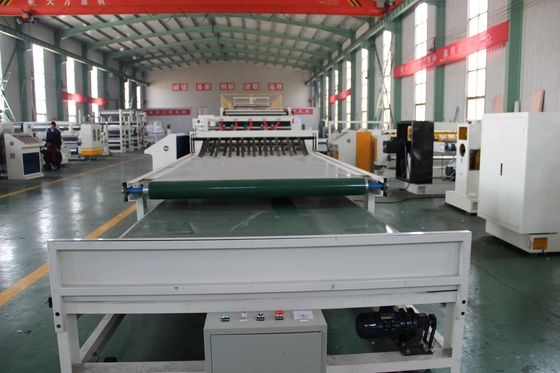

Carton Box Making Machine/boxes Cardboard/corrugated Paperboard Production Line

Product Description

ZJ-V5b Full Hydraulic Shaveless Paper Holder

-

Electric Paper Cart, Guide Rail

★Web automatically up and down. Electric push in place. ★ The whole track is buried, the main frame is no. 18 channel steel, I-steel and ¢20mm cold-drawn round steel welding, guide length of 9000mm. ★Each paper holder with two paper trolley from both sides can be on paper at the same time.

-

RG-3-900

-

Triplepreheater

★The preheating roller conforms to the national standard of a class pressure vessel and is attached with the pressure vessel certificate and inspection certificate. ★The surface of each roll after precision grinding and hard chromium plating treatment, small surface friction, durable. ★ Electric adjustment of wrapping Angle, wrapping Angle can rotate in 360° to adjust the paper heating area. ★ Double speed reducer is used to adjust the Angle of the package, with self-locking function. ★Preheating roller adopts butterfly head design, steam heating.

SF-360E drawer type single side corrugated machine

★ Main flute roll: ¢360mm (varies according to flute type), ¢415mm pressure roll, ¢400mm preheating roll.Negative pressure design, low heat loss. ★ Quick roll change, 10 minutes, just a button switch can be quickly and easily complete the replacement of corrugated roll. ★Corrugated roller adopts 48Crmo high quality alloy steel, the surface after grinding tungsten carbide treatment. ★The corrugated roller, pressure roller, etc. adopt the air bag control system with high stability, and at the same time have the air pressure control buffering effect. ★ Glue quantity control using electric adjustment, rubber separation device electric, glue coating system in the host machine stop can operate independently, to prevent glue dry. ★Mobile gluing system, conducive to maintenance, repair work. ★ Simple operation control system, human nature. ★Built-in preheater with spray system to adjust the temperature and moisture of core paper. ★The main, auxiliary corrugator roller and pressure roller bearing are all lubricated with high temperature to ensure the bearing life and smooth operation.

TQ heavy transport bridge

★ Part of the main framework of the channel steel, I-steel, Angle steel and other connections. ★ Both sides are equipped with safety guardrail and safety herringage pedal, the operation surface is equipped with safety escalator, to ensure the safety of staff and easy to operate. ★ Independent variable frequency motor lifting mechanism, PVC conveyor belt transmission, single-tile cardboard into wavy regular stability. ★The surface of all rolls is ground and plated with hard chrome. ★Vacuum adsorption tension control, suction pipe 5 inches, plus adjustment valve, air volume stepless adjustable. ★ Two sets of electric rectifying device, rectifying baffle USES double guide column positioning, screw drive, positioning fast and accurate, smooth walking. ★Bridge full auxiliary high strength composite plate, smooth and durable, small friction, reduce cardboard transport resistance.

SM-E1 double-sidemachine

★ The surface of the heating plate is ground, the width of the hot plate is 600mm, there are 18 heating plates in total, and the cooling and shaping length is 5 meters. ★The heating plate is made of vessel plate and conforms to the national class I pressure vessel standard with pressure vessel certificate and inspection certificate attached. ★ The hot plate adopts the whole hot plate structure. The pressure plate lifting adopts pneumatic spring structure. ★The upper conveyor belt adopts automatic adjustment on both sides and pneumatic tensioning system 2 sets. ★ The heat conduction pipe of the heating plate is divided into 4 sections to control the temperature, with temperature display.

Gm-20 double layer gluing machine

★ Cots surface after conditioning, inner hole processing, do dynamic balance surface fine grinding and engraved with 32 lines of pit type reticulation, evenly coated, less glue consumption. ★ Cots rotation is controlled by frequency conversion motor plus frequency conversion, by frequency conversion control to ensure the linear speed of cots and double-sided machine synchronization, and can operate independently. ★Automatic circulation glue supply, can effectively control the amount of glue, avoid glue precipitation. ★The surface of all rolls is ground and plated with hard chrome. ★Adopt roller encoder to measure the speed signal of double-sided machine to realize its synchronous operation. ★Glue spreading machine adopts human-machine interface display. ★ Glue amount automatic adjustment control, glue amount with the production speed, automatic adjustment, in automatic mode, can also be manual fine tuning, easy to operate.

Nc-30d computer spiral knife crosscutting machine

★Can store 200 groups of orders, replace the paper cutting specifications quickly and accurately. ★knife shaft transmission gear adopts precision forged steel material high-frequency quenching, to achieve no side gap transmission, the use of advanced keyless connection, high transmission accuracy. ★The blade of the crosscutting machine adopts the steel spiral blade structure, serrated knife. ★ Before and after the paper feeding wheel are using the sun wheel press paper, conveying smooth, uniform pressure, not easy to crush the plate or cause blockage. ★ This model is energy storage braking, the average power consumption is the ordinary NC cutting machine 1/3, save electricity more than 70%, to achieve the goal of saving money.

NC computer thin knife vertical indentation machine

★ Three kinds of pressure line form: convex to concave (three layers of line), convex to concave (five layers of line), convex to flat, three kinds of pressure line form can be electric conversion. The depth of the pressing wheel can be automatically controlled by computer, with good linear shape and easy bending. ★Using thin tungsten alloy knife, sharp blade, service life more than 8 million meters long. ★Knife sharpener for computer control, automatic or manual sharpener, cutting edge sharpener, improve production efficiency. ★Imported synchronous driving device, accurate, long life, low operating noise.

DM-XLM fully automatic gantry stacking machine

★ Gantry stacking. Change order time 5 seconds, can automatically count, automatic out, automatic change order. ★Synchronize with production management system, order management, centralized management, not slow down automatic order change. ★Health tube change order waste less than 700mm. ★ Crawler stacking platform, AC servo control lifting, stacking smooth and tidy; ★ When stack reaches the set amount, the frequency conversion control automatically and smoothly horizontal paper output; ★ Backboard AC servo control positioning, order change when automatic, fast, accurate adjustment; ★The tailgate can be shifted automatically, suitable for stacking small orders; ★Transport side standard with electric transport frame, and double station trolley. ★ Independent sealed control cabinet, electrical equipment in clean, clean environment; ★Color touch screen display, convenient for field operation. ★ Automatic operation control, improve efficiency, save labor, reduce the labor intensity of operators;

ZJZ glue making station system

★ The system paste does not need to use a stabilizer, and paste penetration is strong, and paste is stable, long-term preservation is not stratified. ★ The entire system operation is controlled by the program Settings, and the control system software is designed and developed by the company according to the actual needs of each carton factory, stable and reliable operation. ★ The addition of all materials through the program setting, by PLC control to complete, accurate measurement. ★ The system is equipped with a temperature sensor and temperature display control glue temperature, to ensure that starch molecules more easily soluble in water, while avoiding the quality of glue affected by the environmental temperature and have a greater change. ★ The equipment is equipped with an automatic tank washing program, after each transfer of glue, automatic cleaning tank. ★ The liquid level sensor of each glue point storage tank implements the liquid level monitoring, and THE PLC automatically selects the formula to make paste according to different glue points when the liquid level is low. ★ Shearing, mixing time through the program set by PLC control. ★ Tablets alkalization into liquid alkali, stored in the lye storage tank; The liquid level of the lye transfer tank is controlled by PLC. When it reaches the set low limit, it will be automatically supplied by the lye storage tank through the pump. ★ When the material level of the starch storage tank drops to the material level sensor, the system will automatically alarm prompt adding material and vibration adding material. ★Glue feeding through pneumatic diaphragm pump to the rubber storage tank automatically, controlled by PLC.

|

Model

|

Name

|

Number

|

Note

|

|

ZJ-V5B

|

Full hydraulic Shaftless paper plane

|

5

|

Spindle ¢240mm, hyperbolic heavy rocker, toothed clamp, multi-point brake, hydraulic lift, left and right translation, to medium

|

|

DXC

|

Electric paper cart

|

10

|

24/5000 Electric trolley, double guide rail length of 9000mm, adopts medium plate welding.

|

|

RG-1-900

|

Surface paper preheating cylinder

|

2

|

Cylinder ¢900mm, including pressure vessel certificate. Electric adjustment of the Angle. The paper heating area can be adjusted within 360°.

|

|

RG-1-900

|

Core paper preheating cylinder

|

2

|

Cylinder ¢900mm, including pressure vessel certificate. Electric adjustment of the Angle. The paper heating area can be adjusted within 360°.

|

|

SF-360E

|

Draw-out type One sided corrugated machine

|

2

|

89/5000 ¢360mm corrugated main roller, tungsten carbide spraying treatment, quick replacement of tile roller in 10 minutes by electric trailer, high efficiency and energy saving synchronous belt rotation, maintenance free airbag pressurization, independent glue coating unit, PLC automatic glue control, man-machine interface touch screen display, paper breaking automatic stop and

pressure relief. |

|

MK-360

|

Tile roll Quick change module

|

1

|

Tile roller diameter :360mm, tungsten carbide treatment, the module part includes: two ends of shaft seat, bearing, steam element, pneumatic element, etc.

|

|

DY-C

|

electro-hydraulic Roll change forklift

|

1

|

Large capacity battery, electric walking, hydraulic lifting, centralized control.

|

|

RG-3-900

|

Triple preheater

|

1

|

Cylinder ¢900mm, including pressure vessel certificate. Electric adjustment of the Angle. The paper heating area can be adjusted

within 360°. |

|

GM-20

|

two floor Coating machine

|

1

|

The diameter of cots is 268mm. Each layer is driven by an independent variable frequency motor, and PLC is used to adjust the

gluing gap and man-machine interface. |

|

TQ

|

Heavy transport bridge

|

1

|

Main beam 200mm channel steel, independent variable frequency motor drive paper transfer, adsorption tensioning. Electric

deviation correction. |

|

SM-E1

|

Double-sided machine

|

1

|

The frame is 400 mm gb channel steel, with 600 mm *18 chrome-plated hot plates. The inlet adopts arc hot plates to raise the

temperature of surface paper at high speed, and the whole process is designed with contact plate. PLC automatic control platen. Upper and lower belt automatic deviation correction, temperature display, frequency conversion motor. |

|

NCBD

|

Computer thin knife cutting indentation machine

|

1

|

Tungsten alloy blade, five knife eight wire type, zero pressure wire type. Full servo computer automatic cutter, suction tuyere

width automatic adjustment. |

|

NC-30D

|

Computer screw knife crosscutting machine

|

1

|

Full AC synchronous servo control, energy storage brake, helical cutter structure, helical gear transmission, lubricating oil

pressure protection, 10.4 inch touch screen display. |

|

DM-XLM

|

Computer gantry rectangular stacking machine

|

1

|

Servo drive platform rise and fall, three frequency conversion conveying, automatic counting batch, automatic stacking discharge,

import high strength belt output, paper manufacturing side standard with conveyor frame. |

|

ZJZ

|

Glue making station system

|

1

|

Pipes to be supplied by customers. The glue-making device is composed of carrier tank, main tank, storage tank, rubber pump and rubber pump.

|

|

QU

|

Air supply system

|

1

|

Customers provide their own air source.

|

|

ZQ

|

Steam system

|

1

|

Including steam components such as pipe valves, steam traps and meters in the equipment, the customer provides its own heat source

and pipes. |

|

DQ

|

Electric control cabinet system

|

1

|

Electric control system: adsorption single side machine, drive part, computer thin knife machine, double side machine, glue

coating machine all adopt frequency conversion motor, Delta frequency conversion control system. The operation interface is simple and convenient. The speed display control cabinet is equipped with the functions of speed display, unit call and emergency stop. The main relay adopts German SIEMENS famous brand products. |

Want to Know more details about this product