5ply Corrugated Cardboard Making Machine 150M/Min Work Speed

Product Details:

| Place of Origin: | CN |

| Brand Name: | Aomei |

| Certification: | ISO9001 |

| Model Number: | AoMei -13 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | 100000-150000 USD |

| Packaging Details: | wood |

| Delivery Time: | 45 days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 20 sets per year |

|

Detail Information |

|||

| Voltage: | 380V,220v/380v/440v,220V/380V,220V/380VCan Be Customized According To The Customer,380V/220V | Condition: | New |

|---|---|---|---|

| Type: | Packaging Line,Feeding Paper To Corrugation Machine/single Facer,NC--200N,Corrugating Machine | After-sales Service Provided: | Engineers Available To Service Machinery Overseas,Video Technical Support,Online Support,Field Maintenance And Repair Service,Field Installation |

| Automatic Grade: | Automatic,Semi-Automatic | Weight: | 60T,3500kg-7500kg,800--2000kg,250kg |

| Dimension(l*w*h): | Depends On Configurations,10.5*1.6*1.6m,4200x2200x2000,3850*1600*1650mm,60X3.5X2.5 | Certification: | CE,ISO,ISO9001 |

| Driven Type: | Electric,Hydraulic,Mechanical | Application: | Machinery & Hardware,Commodity,Beverage,Food,Chemical |

| Packaging Material: | Plastic,Paper,Wood,Metal,Glass | Packaging Type: | Cartons,Film,Case,Bottles,Belt |

| Warranty: | 1 Year,12 Months,2 Years,one Year,Electrical Mill Roll Stand | Power: | About 100kw,4.2-5.1KW,45kw,25kw-50kw,as Requested |

| Name: | Double Wall Corrugated Cardboard Making Machine,ML Creasing And Cutting Machine,packaging Line,5 Ply Fully Automatic Box Corrugated Cardboard Making Machine Price | Product Name: | NC--200N Helical Knives NC Cutting Machine,corrugated Cardboard Production Line Carton Box Making Machine,Automatic Corrugated Carton Packing Machine,2 Ply Corrugated Paperboard Production Line,kraft/cardboard/corrugated Paper Making Machine Price |

| Usage: | Making Carton,Hydraulic Mill Roll Stand Of Corrugated Cardboard Packing Machine,Corrugated Box,CORRUGATING CARDBOARD | Function: | High Efficiency,Make Two Single Layer To 2ply Corrugated Board,Corrugated Board Making Machinery,For Cardboard Corrugation Making,making Paper |

| Machine Type: | Carton Packaging Machinery,Sealing Packing Machine,Corrugated Paperboard Making Machine,Hydraulic Or Electric Type | ||

| Highlight: | 5ply Corrugated Cardboard Making Machine,Corrugated Cardboard Making Machine 150M/Min,5ply Corrugated Making Machine |

||

Product Description

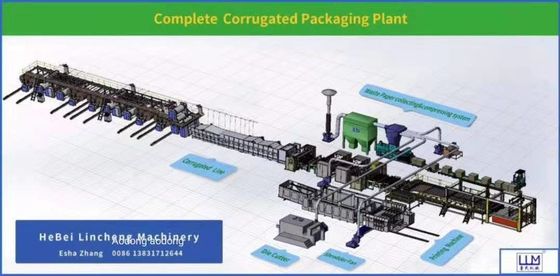

Free Instructions About 5ply The Carrugated Paperboard Production Line

![]()

Main Technical Parameter of 5 Ply Corrugated Production Line:

1. Design speed:158 m/min

2. Work speed:150 m/min

Note: Production line speed test: paper should meet the following requirements:

1) Base level not less than B level

2) Base paper moisture content 11%±1%

3) Surface paper: 120-200g/m2

4) Corrugated paper: according to flute type

5) Core paper: 125-200g/m2

3. Working width:1800mm

4. Production line length:about 85 m(Subject to the final drawings)

5. Flute type:A,B,C,E,F choice

6. Steam demand:2.5-3tons/ hour;

Steam: Max pressure 1.3Mpa Common pressure 0.8 --1.2Mpa

7. Power: 380V 50Hz (according to customers’ required)

8. Transmission direction: Right or left operation according to customers’ required

9. In case of technology changes prior notice.

10. Default Color as orange for all moving parts for harzard purpose, milk white for main body with dark blue straps. Or customized color according customers’ requirment.

![]()

Note: Customer’s self –preparing material and issue:

1. Compressed air pipelines, glue pipelines

2. Power, electrical wire to operation box

3. Water pipelines, water barrel, electrictiy and all wiring to control box and motor of machine

4. 4-6 ton boiler, steam ground foundation, steam piping to machine side

5. Raw materials (paper roll, corn starch, caustic soda, sodium borax) to test machinery

6. Engine oil, lubricating oil and hydraulic oil

7. Installation cost such as lifting, transaction and commissioning;

8. electric and water should be ready before instllation arrive;

9. The ground map will be sent to client before machine arrive client’s plant, the foudation could be ready for insllation before unload the machines..

Installation Request:

1, Seller’s 3 qualified technicians will be sent to client’s plant for installaion supervising, on

electrician, one mechnical personel and one computer expert. Rount Air ticket and local accomodation and meal cost will be covered by client, and 80USD per day per person for mechnic and electric personel, and 100USD per day per person for computer personel.

2, Seller will have a 5-8 persons installation team for installing machine, and certain amount ofpersonel for welding works and also the piping for boiler to corrugating line.

3, Before the installation team arrives, custoemr should have industrial and normal lighting electricity, installed boiler and water ready, especially the electricity wired production warehouse must has very good grounding arrangement, and unsufficient or inproper grouding may cause affection on the inverter, computer and drivers of the machineries.

4, Customer may have the installation foudation been prepared ready as the confirmed foudation map in order to speed up the installation and process.

1. Customer should prepare or rent all necessary euipments and tools includes but not only crane, forklift, specical clamps.![]()